Energy

Precision manufacturing for hydrogen fuel cells

Feintool engineers use synchrotron analysis to optimise processing of extremely thin stamped metal sheets.

Feintool is a technology and market leader in processing sheet steel. The company is constantly pushing the boundaries developing state-of-the-art manufacturing in high volumes for demanding automotive and industrial applications.

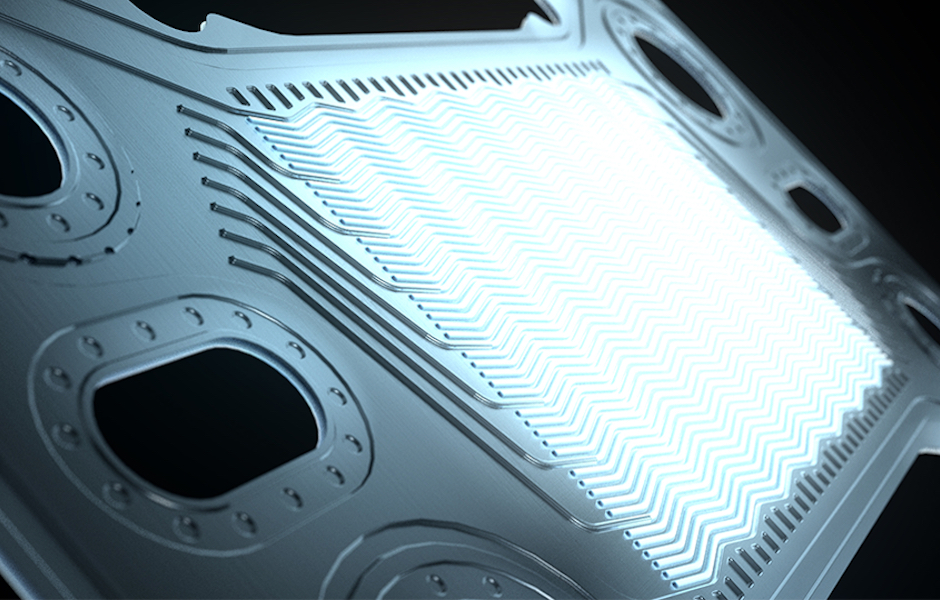

FEINforming is a manufacturing process developed by Feintool that enables the precise processing of extremely thin metal sheets. It enables a leap in quality in the production of bipolar plates, the central component of PEM fuel cells installed in vehicles.

What makes a fuel cell powerful?

The goal is to fit as much power as possible into the smallest possible space. Depending on their capacity, several hundred individual fuel cell modules are connected into a fuel cell stack. The thinner the individual cell, the more compact the design, the lower the total weight, and the higher the power density.

As the core element of the fuel cell stack, bipolar plates are the component that can play a decisive role in the breakthrough performance of the fuel cell.

Between the bipolar plates, hydrogen and oxygen react to form water, releasing energy in the form of electricity and heat. Each bipolar plate contains extremely fine channels on both sides through which hydrogen and oxygen gas flow and react. Water, the reaction product, is also removed through the channels.

Unique manufacturing insights from synchrotron analysis

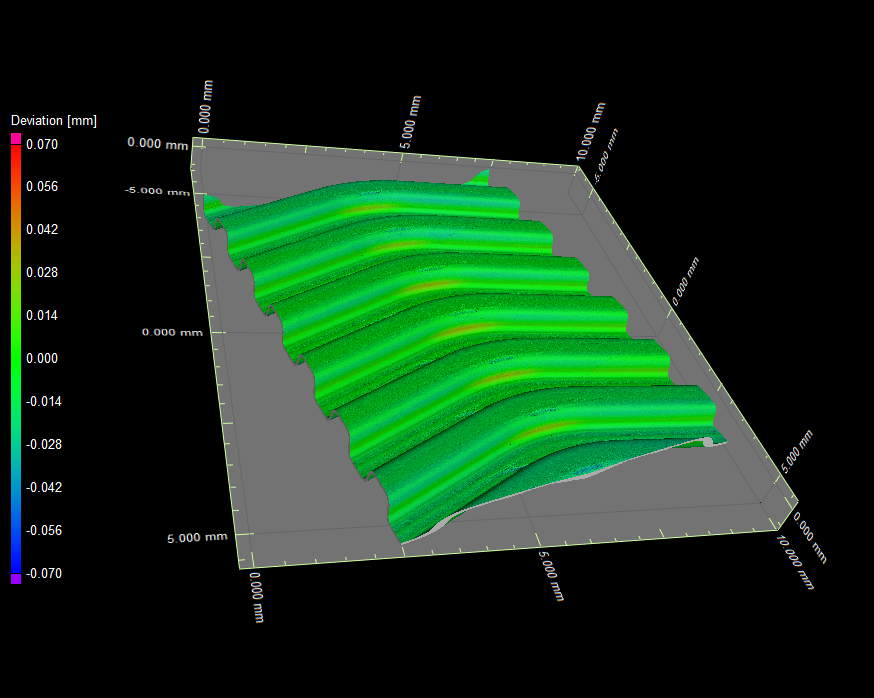

The geometrical properties of the bipolar plate channels play a critical role in the efficiency of the chemical and physical processes.

The geometrical properties of the bipolar plate channels play a critical role in the efficiency of the chemical and physical processes.

The cathode and anode sheets of a bipolar plate must fit together perfectly within a few micrometres to ensure gas-tight laser welding.

FEINforming is a precision technology that allows the thinnest stainless steel sheets to be formed with extreme accuracy and minimal fault tolerances.

Working with expert teams from ANAXAM, the Technology Transfer Center for Advanced Manufacturing, Feintool’s engineers used high-resolution x-ray computed tomography (CT) at the Swiss Light Source to non-destructively and three-dimensionally characterise bipolar plates with the thinnest material thicknesses and minimal tolerances.

Using synchrotron x-ray CT, Feintool achieved an otherwise unattainable combination of measurement accuracy and resolution in the 3D microstructures of the stamped metal parts.

The results helped Feintool to further optimise the interaction between press and tools, making a significant contribution to the development of the manufacturing technology to ensure the highest precision of the bipolar plates.

References

High-performance fuel cells through FEINforming: the key to future mobility

Investigation of bipolar plates for fuel cells using high-resolution synchrotron CT