Advanced Materials

Alloying at high temperatures

Real-time imaging of the microstrucure of aluminium-copper alloys helps to optimize their mechanical properties.

Understanding the formation of materials at elevated temperatures is critical for determining their final properties. At the Swiss Light Source, a 300 W infrared laser heating system is available to provide controlled localised heating up to 1800º C.

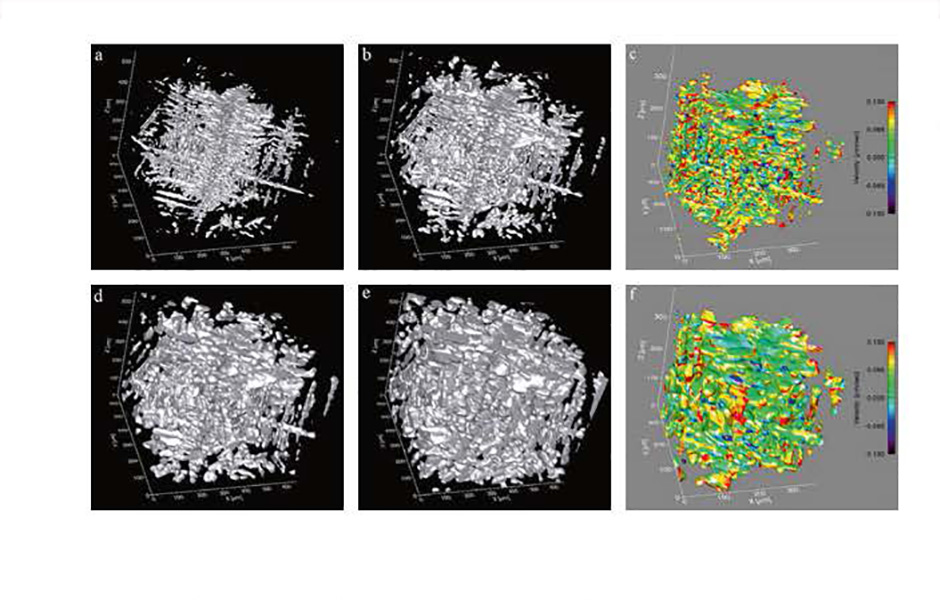

In this example, as an aluminium-copper alloy was cooled from above the melting point, ultra-fast 3D x-ray tomographic microscopy captured the velocity of the evolving solid interface and dendrite growth with 1.1 µm pixel size. Real-time data on the solidification of the alloy revealed the formation of the microstructure and how fast the solid-liquid evolution occurred.

References

Development of a laser-based heating system for in situ synchrotron-based x-ray tomographic microscopy

Fife JL, Rappaz M, Pistone M, Celcer T, Mikuljan G, Stampanoni M

Journal of Synchrotron Radiation. 2012;19:352.

https://doi.org/10.1107/S0909049512003287

Financing of this work through the Swiss Competence Centre of Materials Science and Technology (CCMX) and its industry partners Asulab, Constellium, Kugler Bimetal, Novelis, Rolex and Varinor.